ATEX motors for hazardous areas

ATEX motors for hazardous areas

Fabrika’s line of explosion-protected ATEX motors that are intended for use in potentially explosive atmospheres includes motors for all zones: 1, 2, 21 and 22.

The first step is to classify hazardous areas as one of the zones. The end user is themselves responsible for classifying hazardous areas. Directive 1999/92/EC provides information regarding the “Classification of places where explosive atmospheres may occur”. The corresponding standards of reference are EN 60079-10-1 for gas and EN 60079-10-2 for dust.

Table 1 below is a step-by-step guide to choosing motors:

Table 1: ATEX zones defined and explained

The different categories are explained in the following section.

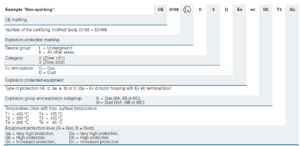

- CE marking: indicates that the device meets CE requirements

- Number of the certifying “notified” body: indicates the certification body with its unique number

- Explosion protection marking: indicates that the electrical equipment is explosion-protected

- Device group:

- I: includes electrical equipment intended for use in underground areas such as mines (Fabrika cannot supply motors for this group)

- II: includes equipment intended for use in other areas likely to become endangered by explosive atmospheres (surface plants that are not mines)

- Category: Group II is subdivided into two categories:

- Category 2/zone 1 and 21: high level of protection

- Category 3/zone 2 and 22: normal level of protection

- Ex atmosphere: indicates whether the equipment is placed in an atmosphere containing dust (D) or gas (G)

- Explosion-protected equipment: is marked with “Ex” regardless of zone

- Type of protection: Fabrika’s electric ATEX motors can have the following types of protection:

- Ex db: encapsulated motor and terminal box for zone 1, gas

- Ex db eb: motor Ex db (encapsulated) and terminal board Ex eb (increased safety) for zone 1, gas

- Ex eb: increased safety for zone 1, gas (N.B.: frequency converter function not allowed for this ATEX-type motor)

- Ex ec: non-sparking for zone 2, gas (formerly Ex Na)

- Ex tb: protection by enclosure t for zone 21, dust

- Ex tc: protection for zone 22, dust

- Explosion group and explosion subgroup:

- II: Gas (N.B.: IIC is the group with the most stringent requirements and also covers IIB and IIA. IIB also covers IIA):

- IIC: hydrogen, acetylene, carbon disulfide

- IIB: diethyl ether, ethylene, etc.

- IIA: propane, butane, pentane, natural gas, etc.

- III: Dust

- II: Gas (N.B.: IIC is the group with the most stringent requirements and also covers IIB and IIA. IIB also covers IIA):

- Temperature class with max. surface temperature: the motors are put in a temperature class depending on their maximum surface temperature (N.B.: the higher the T value, the higher the protection in the motor temperature class. For example, temperature class T4 covers temperature class T3 and so on)

- Equipment protection level: indicates the protection level of the electrical equipment

Table 2: A visual illustration of ATEX zones

ATEX – the background

“ATEX” is the abbreviation of the French term for explosive atmospheres, “atmosphères explosibles“. In the European Union, explosion protection is regulated by directives and laws.

In 1994, the EU issued the EC Directive 94/9/EC “on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres“ for this purpose. Article 95 of this directive (before 1997: 100a) addresses manufacturers and importers of explosion-protected equipment and regulates the marketing of such equipment by defining types of construction, certification, manufacturing and quality assurance, marking, operating instructions and declaration of conformity. This directive is unofficially known as “ATEX 95” or “100 a” in technical circles.

There is also Directive 99/92/EC (“ATEX 137”; still called “ATEX 118a” before 1997). This addresses companies’ operating equipment (workstations and places of work) and makes them responsible for evaluating the danger of explosion at the place of use. In other words, companies must precisely define which type or “category” of explosion protection their equipment actually requires.