Cooling methods for electric motors

Cooling methods for electric motors

Cooling an electric motor means transmitting the losses that occur in the motor, turning them into heat and releasing them into the external environment. The aim is to keep the temperature of insulating materials below their limit values.

Most standard Fabrika and Siemens electric motors are cooled using self-ventilation (IC 411 in accordance with DIN EN 60034-6) and are fitted with a synthetic two-way axial fan mounted on the non-drive end of the shaft.

The main cooling methods used by our motors are as follows:

With fan:

- IC 411: self-ventilated surface-cooled motor (TEFC)

- IC 416: separately ventilated, surface-cooled (TEFC) motor with separately mounted, powered fan

Without fan:

- IC 418: without fan and fan cover, e.g. fan in the air flow driven by the motor

In accordance with DIN IEC 60034, there exist two systems for coding cooling types, both of which start with the letters “IC” (= International Cooling).

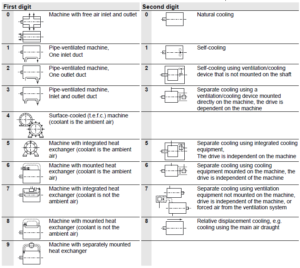

To produce the “full coding”, the letters IC are following by two blocks, each comprising one letter and two digits, e.g. “IC W37 A71”. In the German draft standard – for air-cooled motors – users are recommended to use “simplified coding”, which only has two digits after the letters IC. The first digit defines the coolant circulation method and the second digit the type of drive used to move or pump the coolant, as shown in Table 1:

Table 1: Cooling methods for electric motors in accordance with DIN IEC 60034, Part 6

Minimum distance when mounting motors

When motors are mounted, a minimum gap must be maintained between the fan cover and the closest object to it, so that the air circulation is not compromised. As a rule of thumb, this minimum distance should be half the axle height. A minimum gap the same size as the fan cover is recommended for easier access for servicing purposes.

From frame size 63 upwards, motors can be supplied with an independently driven external ventilator if required. This is also referred to as “forced ventilation” and defined as cooling method IC416. In this case, cooling is provided by an axial ventilator mounted in place of the standard fan cover. This design should be used in cases where the motor is operated using a frequency converter with a very low frequency. A motor with forced ventilation can be operated at constant torque at low rotation velocity or when there is a broad range of rotation velocity. This option is not available for motors with a second shaft end.