Sustainable and energy efficient PM motors from Fabrika

With Fabrika’s energy efficient permanent magnet motors, we can help you and your company reach your sustainability goals and ensure energy savings for your electric motors and application whether it is a ventilation, pump, compressor or something else.

Contact us already now to hear more about the technical advantages which a PM motor can bring your series production or send us an enquiry already now!

Contact us now! PM motors specs.At Fabrika, we are spezialised in

permanent magnet (PM) motors for OEM and machine builders

in larger quantities

All your advantages with a PM motor at a glance

- Very high energy efficiency due to PM motor technology!

- Compact design with constant torque throughout the whole speed range!

- Combination with VFD ensures a very flexible setup where you can adjust the speed of the motor to your specific duty point!

- Total cost of ownership lower than the equivalent AC induction motor!

What is a PM motor and how does it work?

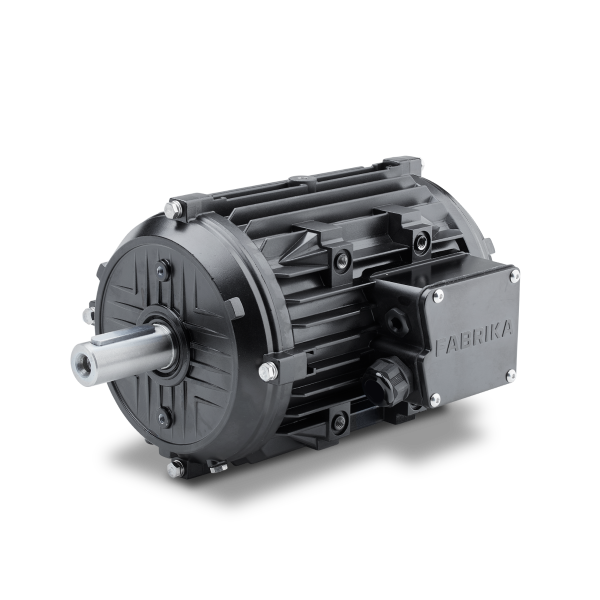

A permanent magnet motor looks from the outside more or less the same as an equivalent AC induction asynchronous motor with housing, stator and rotor, terminal box and a shaft mounted on to the rotating rotor.

On the inside, the PM motor is different from the AC motor, though, with permanent magnets mounted on the rotor. In this way, the magnetic field of the motor is already established even before power is connected through the terminal box.

Also the lamination design of the rotor of the PM motor is different than from the AC induction motor with improved characteristics to ensure highest energy efficiency, constant torque over the whole speed range of the motor as well as a compact design with more torque compared to the equivalent AC motor, which is very useful when there is not much space in the application.

The PM motor works also more or less with the same principles as the AC motor where power is connected to the windings of the stator through the terminal board and phases connected – the forces make the rotor with the mounted shaft rotate and the PM motor is able to turn electrical energy into mechanical energy and drive e.g. a ventilator, a pump or something else.

Because of the design of the PM motor, a frequency converter is needed to determine the position of the poles compared to the stator. This also means that a PM motor runs synchronous with the magnetic fields aligned and not asynchronous with slip like known from the AC motor.

Benefits of the PM motor

PM motors are usually much more efficient than traditional AC motors. In difference to AC motors, PM motors do, as written above, not need to generate a magnetic field, as they are equipped with permanent magnets which ensures a static magnetic field even before the power is connected. Because of this, there is no need to use energy on inducing a magnetic field in the PM motor, making it very energy efficient compared to an AC motor.

PM motors require also a variable frequency drive (VFD) to be operated. With the use of a frequency converter, there are great possibilities to reduce the power consumption further by being able to lower the speed of the PM motor. The combination of motor and VFD ensures a very flexible setup where you can adjust the speed of the motor to your specific duty point.

Great torque characteristics on a PM motor

Because of a higher torque density of the PM motor, it can deliver more power than the equivalent frame size AC motor. This is a great advantage for applications where the space is limited.

Further, the PM motor has constant torque throughout the whole speed range compared to AC motor which have a specific torque at a specific speed. This makes the PM motor more versatile and also great for applications like HVAC.

Applications perfect suited for PM motors

Our PM motors can be fitted to suit different applications as those listed below. Is your application not listed, then please do not hesitate to contact us, we are here to ensure that you get the best solution for your application, and we have experience with highly customized solutions, e.g. special voltage, different speed characteristics or a special design.

Agricultural ventilation:

We have a good experience in delivering motors for ventilation systems placed in livestock barns. The environment here is usually harsh, as there is a high concentration of chemicals as e.g. ammonia. For us it is an important factor that the motors we provide do not corrode at these conditions. Therefore, a special surface treatment called Cathodic Electro Deposition (CED), where the colour is bound electrically to the aluminium, is used on all our motors for this application. This method prohibits chemical to enter between the paint and the aluminium, which usually results in corrosion if exposed for longer periods.

For this application we use the following, options:

- IP65 ingres protection

- CED surface treatment

- Possibility for custom mounting solution to fit in your fan

Cooling towers:

Motors used for cooling towers are exposed to environments where the relative humidity is up to 100% and motors are at risk for corrosion. Fabrika PM motors are designed for reliable operation at these conditions, by the use of these options:

- Tropicalization (inner epoxy coating)

- Drain plugs with a labyrinth, to ensure that condensation is drained automatically

- Special sealing construction at shaft opening, ensuring long life time of the seal and protects against ingress

Blast freezers:

Motors which are used inside blast freezers are exposed to low temperatures. Fabrika PM motors for blast freezers are designed to start and operate in conditions down to -40°C, by adding these options to the motor:

- SKF WT bearings, which are designed to operated at low temperatures

- All rubber and plastic parts are checked against brittleness at low temperatures (down to -40°C)

Contact us already now to hear more.

Specifications of Fabrika PM motors

Fabrika’s assortment of PM motor consists of a series of motors with emphasis on high energy efficiency. The product range is available with the following characteristics:

- Output power between 0.35 – 160 kW

- Revolutions from 400 – 6000 RPM

- Rated voltage 190V – 620V

- Efficiency between IE4 and IE5

- Build according to IEC 60034

- Protection class IP55 – IP65

- Frame sizes between 71 – 280

- Mounting designs: B3, B5, B35, B14 and the equivalents for vertical mounting

- Cooling method: Totally Enclosed Fan Cooled (IC411) or Totally Enclosed Air Over (IC418)

- Thermic protection (PTO, PTC and PT100)

- Bearing: Either sealed (2RS) or shielded (2Z)

- Possibility for customized solution

- Dimensions are sized according to the standard EN 50347

Cost of ownership with an energy efficient PM motor from Fabrika

How much can you save by using a PM motor instead of an AC motor?

Price example!

- 2.2 kW 4 pole IE3 AC motor at 50 Hz -> 86.7% -> Input power = 2537 W

- 2.2 kW IE5 PM motor at 1500 rpm -> 91.4% -> Input power = 2407 W

- Energy saving 130 W per hour -> 569 kWh per year assuming 12 hour per day -> 71 EUR per year per motor (0.1254 €/kWh2)

- For comparison a cost of 2.2 kW 1500 rpm PM ≈ 143€

Conclusion: PM-motor can pay for themselves in approx. 2 year.

Difference between a PM and AC can be achieved even faster!

International focus on energy savings

In recent years, new requirements for electric motors have emerged through new legislation and an increased focus on sustainability in the entire industry. With appr. 8 billion electric motors in the EU standing for around 45% of the total energy consumption, and due to increased energy costs, energy efficiency is more important then ever. Therefore, the energy efficient motors like permanent magnet (PM) motors will be in focus in the future, and here we are ready to help you!

With Fabrika’s energy efficient permanent magnet motors, we can help you and your company reach your sustainability goals and ensure energy savings for your electric motors.