Types of construction of electric motors

Types of construction of electric motors

When choosing the right electric motor for your application, the mounting method needs to be considered. The mounting method, or design type, of electric motors is standardised in accordance with DIN IEC 34, Part 7.

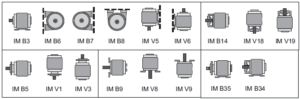

Table 1: Types of construction in accordance with DIN IEC 34, Part 7

There are three main types of design commonly used for electric motors:

- Foot-mounted types (B3)

- Foot- and flange-mounted types (B35 and B34)

- Without feet, flange-mounted types (B5 and B14)

The mounting method for an electric motor is represented by the two letters “IM” (International Mounting) plus the specific code, e.g. B3, B5, V1, etc.

In addition to the commonly used basic IM B3 design type, motors can also be supplied with other types of design. Smaller motors up to frame size 160 will ideally have an IM B14 design with a large or small flange instead of an IM B5 design.

With IM B5, the fixing screws or bolts are inserted from the motor through the holes in the flange. The IM B14 flange has threaded holes to attach the motor to the machine being powered.

Vertical types of design are also often fitted with a canopy, especially when installed outdoors. This feature is specified for all explosion-protected motors from Siemens where the shaft faces downwards. For shafts facing upwards, solid parts must be prevented from falling into the fan cover.